Anatomy and Physiology 1 Study Guide PDF: A Comprehensive Plan

This comprehensive plan offers a detailed PDF study guide, covering essential A&P 1 topics like anatomical branches, structural levels, and human body systems for effective learning․

Anatomy and Physiology 1 (A&P 1) serves as the foundational course for students pursuing healthcare careers․ This initial exploration delves into the intricate structure and function of the human body, establishing a crucial base for advanced studies․

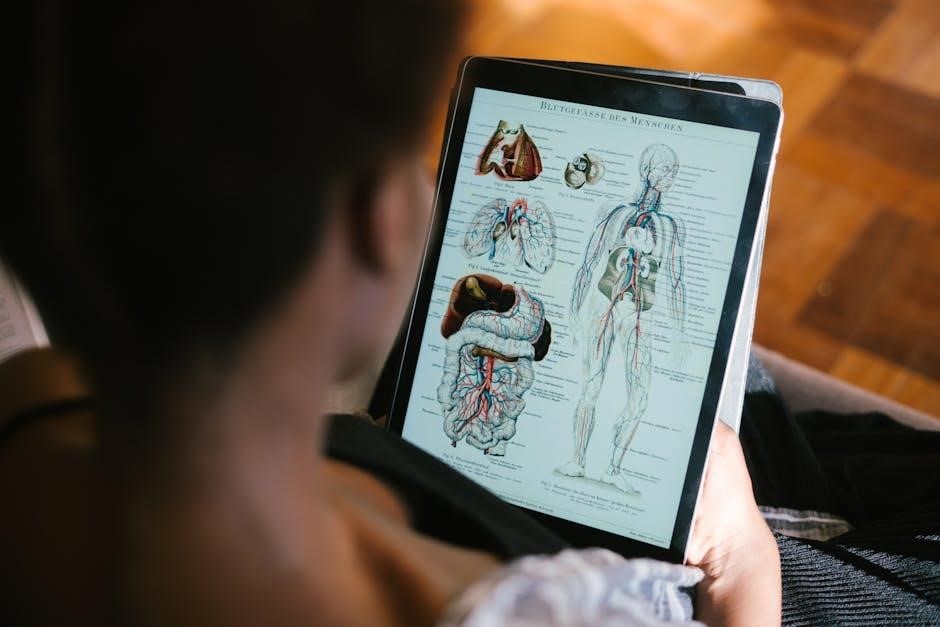

Effective learning in A&P 1 relies heavily on utilizing study guides, as they distill complex information into manageable segments․ These guides, often available as PDFs, are designed to supplement lectures and textbooks, highlighting key terms and concepts․ Remember, these guides aren’t exhaustive; they guide your learning, but lecture content and textbook readings remain vital․

Success in this course demands understanding the definitions of various anatomical and physiological branches, alongside grasping the hierarchical levels of structural organization – from chemical to organismal levels․

What is Anatomy?

Anatomy is the study of the body’s structure – examining how parts are organized and relate to one another․ It’s a fundamental component of A&P 1, providing the blueprint for understanding physiological processes․ Several branches exist, each offering a unique perspective․

Gross anatomy, or macroscopic anatomy, focuses on structures visible to the naked eye, while microscopic anatomy requires tools like microscopes to observe cells and tissues․ Further specialization includes histology – the study of tissues – and cytology, focusing on individual cells․ Surface anatomy examines external features․

A solid grasp of anatomical terminology is crucial․ Study guides often emphasize defining these branches and recognizing examples of each, aiding in comprehension and exam preparation․ Understanding anatomy is the first step towards understanding how the body functions․

What is Physiology?

Physiology investigates the functions of the body’s structures – how they work, individually and collectively, to maintain life․ It complements anatomy, explaining why things are structured as they are․ A&P 1 study guides emphasize understanding these functional mechanisms․

Physiological processes occur at multiple levels, from cellular activities to the integrated operation of entire organ systems․ Key areas include examining how muscles contract, how nerves transmit signals, and how organs exchange gases․

Distinguishing between anatomy and physiology is vital; anatomy describes what is, while physiology explains how it works․ Effective study involves linking structural details (anatomy) to their corresponding functions (physiology) for a holistic understanding․

The Branches of Anatomy

Anatomy encompasses several specialized branches, each offering a unique perspective on the body’s structure․ Gross anatomy, or macroscopic anatomy, examines large structures visible to the naked eye, like organs and muscles․ Conversely, microscopic anatomy delves into structures requiring magnification․

Within microscopic anatomy, histology studies tissues, while cytology focuses on individual cells; Surface anatomy explores external features and their relation to deeper structures․ A&P 1 study guides often categorize content by these branches․

Understanding these distinctions is crucial for effective learning․ Knowing whether a topic falls under gross or microscopic anatomy helps focus study efforts․ These branches provide a framework for organizing and comprehending the body’s complex architecture․

Gross Anatomy

Gross anatomy, also known as macroscopic anatomy, involves the study of structures that can be seen with the unaided eye․ This branch focuses on the larger features of the human body, including organs, muscles, bones, and nerves․ It’s a foundational element within A&P 1 study guides․

Students learning gross anatomy often utilize dissection, observation, and palpation to understand spatial relationships and structural organization․ A strong grasp of gross anatomy is essential for understanding how body systems interact․

Effective study involves visualizing structures and their locations․ Resources like anatomical models and detailed diagrams are invaluable․ Mastering gross anatomy provides a crucial base for further exploration of physiological processes․

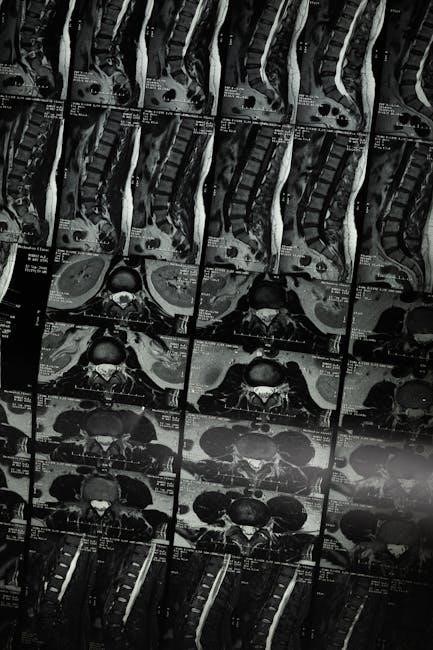

Microscopic Anatomy

Microscopic anatomy delves into the realm of structures too small to be seen without magnification․ This branch utilizes microscopes to examine cells, tissues, and their intricate components, forming a vital part of any A&P 1 study guide․ It’s crucial for understanding the functional units of the body․

Students studying microscopic anatomy will encounter various staining techniques to enhance visualization․ Understanding cellular structures like organelles and tissue types is paramount․ This knowledge builds a foundation for comprehending physiological processes at a cellular level․

Resources like histology slides and detailed micrographs are essential for effective learning․ Mastering microscopic anatomy requires diligent observation and a strong understanding of cellular biology․

Histology

Histology, a specialized branch of microscopic anatomy, focuses specifically on the study of tissues․ A comprehensive A&P 1 study guide must include detailed coverage of the four primary tissue types: epithelial, connective, muscle, and nervous tissue․ Understanding their structures and functions is fundamental․

Students will learn to identify tissues under a microscope, recognizing key characteristics like cell shape, arrangement, and extracellular matrix composition․ Histological techniques, including staining and preparation methods, are also important to grasp․

Effective histology study involves utilizing prepared slides, virtual microscopy, and detailed diagrams․ This knowledge is crucial for understanding how tissues contribute to organ function and overall body physiology․

Cytology

Cytology, another branch of microscopic anatomy, centers on the study of cells – the fundamental units of life․ An effective A&P 1 study guide PDF will dedicate significant attention to cellular structures and their functions․ This includes detailed exploration of organelles like the nucleus, mitochondria, ribosomes, and endoplasmic reticulum․

Understanding cell membrane transport, cell division (mitosis and meiosis), and cellular communication are vital components․ Students should be able to identify cellular components under a microscope and correlate structure with function․

Resources like labeled diagrams, interactive models, and virtual labs enhance cytology learning․ Mastery of cytology provides a foundation for understanding tissue and organ physiology․

Surface Anatomy

Surface anatomy focuses on the external features of the body and their relationship to deeper structures․ A robust A&P 1 study guide PDF will incorporate visual aids like anatomical illustrations and photographs to aid in identifying superficial landmarks․

This branch is crucial for palpating (feeling) structures like bones, muscles, and blood vessels through the skin․ Understanding surface anatomy is essential for clinical applications, such as locating injection sites or assessing physical exam findings․

Study guides should include exercises where students predict the location of underlying organs based on external cues․ Mastering surface anatomy builds a strong spatial understanding of the human body․

Levels of Structural Organization

A key component of any A&P 1 study guide PDF is a thorough exploration of the levels of structural organization; These levels demonstrate increasing complexity, starting with chemical level – atoms and molecules – forming the building blocks of life․

Next is the cellular level, where molecules combine to form cells, the basic structural and functional units․ These cells then organize into tissues, groups of similar cells performing specific functions․ Organs, composed of different tissues, carry out complex tasks․

Multiple organs working together create systems, like the skeletal or muscular system, and finally, all systems integrate to form the complete organismal level – the human body․ Understanding this hierarchy is fundamental․

Chemical Level

The chemical level, foundational to anatomy and physiology, represents the most basic organization of matter․ This level encompasses atoms – like hydrogen, oxygen, carbon, and nitrogen – which are the smallest units of an element․ These atoms combine to form molecules, such as water (H2O), proteins, carbohydrates, and lipids․

Understanding the structure and interactions of these molecules is crucial․ For example, proteins dictate cellular function, while carbohydrates provide energy․ A solid A&P 1 study guide PDF will emphasize the importance of chemical bonds – ionic, covalent, and hydrogen – in maintaining molecular integrity․

This level sets the stage for all higher levels of organization, demonstrating how life’s complexity arises from simple chemical interactions․

Cellular Level

Building upon the chemical level, the cellular level represents the basic structural and functional unit of the body – the cell․ Cells are composed of various organelles, each performing specific tasks to maintain cellular life․ These include the nucleus (containing DNA), mitochondria (energy production), and ribosomes (protein synthesis)․

A comprehensive A&P 1 study guide PDF will detail cell structures and their functions․ Understanding cell membrane transport – diffusion, osmosis, and active transport – is vital․ Different cell types, like muscle cells and nerve cells, exhibit specialized structures reflecting their unique roles․

Cells are the smallest units capable of carrying out life processes, forming the foundation for tissues and organs․

Tissue Level

At the tissue level, similar cells performing a specific function are organized into tissues․ A quality anatomy and physiology 1 study guide PDF will emphasize the four primary tissue types: epithelial, connective, muscle, and nervous tissue․

Epithelial tissue covers surfaces and forms linings, connective tissue supports and connects organs, muscle tissue enables movement, and nervous tissue transmits signals․ Understanding the structure and function of each tissue type is crucial․

The study guide should cover tissue organization, including simple vs․ stratified epithelia, different types of connective tissue (bone, cartilage, blood), and the characteristics of skeletal, smooth, and cardiac muscle․

Organ Level

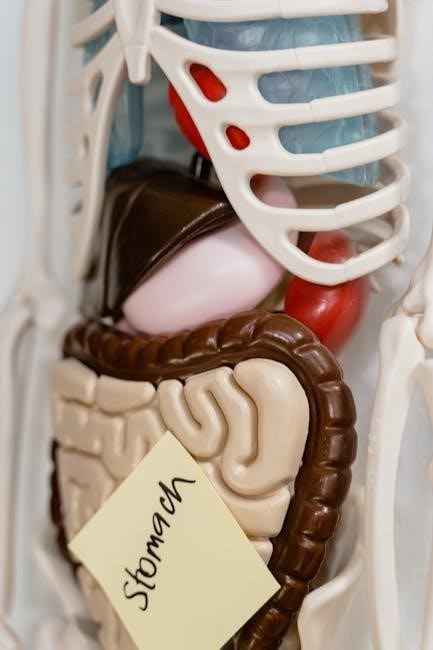

The organ level represents the combination of different tissues working together to perform specific functions․ A robust anatomy and physiology 1 study guide PDF will detail how various tissues collaborate within organs like the heart, lungs, or stomach․

For example, the stomach comprises epithelial tissue for lining, muscle tissue for churning, connective tissue for support, and nervous tissue for regulation․ Understanding this interplay is vital․

The study guide should emphasize organ structure, function, and how organs interact within organ systems․ It should cover key organs and their roles, preparing students for detailed system-level studies․

Focus on how the arrangement of tissues contributes to the organ’s overall functionality and efficiency․

System Level

The system level in an anatomy and physiology 1 study guide PDF focuses on groups of organs cooperating to achieve a common purpose․ These systems, such as the cardiovascular or respiratory system, demonstrate integrated functionality․

A comprehensive guide will explain how organs within a system interact, detailing the flow of blood through the cardiovascular system or air through the respiratory system․ Understanding these connections is crucial․

The PDF should cover the major body systems – skeletal, muscular, nervous, digestive, and more – outlining their components and coordinated actions․ Emphasis should be placed on how systems depend on each other for overall body homeostasis․

Detailed diagrams and explanations of system interactions are essential for effective learning․

Organismal Level

The organismal level, within an anatomy and physiology 1 study guide PDF, represents the highest level of structural organization – the complete living being․ This level emphasizes the sum of all structural levels working in unison to maintain life․

A quality PDF will illustrate how all systems integrate to support organismal functions like respiration, digestion, and reproduction․ It highlights the interconnectedness of body parts and their contribution to overall health․

Understanding the organismal level requires grasping how disruptions at lower levels (cellular, tissue) can manifest as disease or dysfunction at the organism level․

The study guide should provide examples of how the body responds to stimuli and maintains homeostasis as a whole, functioning organism․

The Human Body Systems

A robust anatomy and physiology 1 study guide PDF meticulously details each human body system․ Expect comprehensive coverage of the Skeletal System, outlining bone structure and function, and the Muscular System, detailing muscle types and movement․

Crucially, the Nervous System’s role in control and communication, the Cardiovascular System’s circulatory functions, and the Respiratory System’s gas exchange are thoroughly explained․

Furthermore, a good PDF will cover the Digestive System’s breakdown of nutrients, the Endocrine System’s hormonal regulation, and the Reproductive System’s functions․

These sections should include key structures, physiological processes, and common pathologies, aiding in a holistic understanding of bodily functions․

Skeletal System

An effective anatomy and physiology 1 study guide PDF dedicates significant attention to the Skeletal System․ It should detail bone classifications – long, short, flat, irregular, and sesamoid – alongside their respective functions․

Key areas include bone structure (compact and spongy bone), bone development (ossification), and joint classifications (fibrous, cartilaginous, synovial)․ The guide must cover major bones of the axial and appendicular skeletons․

Furthermore, understanding skeletal disorders like osteoporosis and arthritis is vital․ Diagrams illustrating bone anatomy and joint types are essential for visual learners․

A quality PDF will also explain the skeletal system’s role in support, protection, movement, mineral storage, and blood cell formation, providing a complete overview․

Muscular System

A robust anatomy and physiology 1 study guide PDF thoroughly explores the Muscular System, detailing the three muscle tissue types: skeletal, smooth, and cardiac․ It should explain the hierarchical structure, from muscle fibers to fascicles and finally, the whole muscle․

Crucial concepts include muscle contraction mechanisms – focusing on the sliding filament theory – and the roles of actin, myosin, and calcium ions․ The guide must cover major skeletal muscles, their origins, insertions, and actions․

Understanding muscle fatigue, different types of muscle contractions (isotonic, isometric), and common muscle disorders is essential․

Visual aids like diagrams illustrating muscle anatomy and contraction processes are invaluable․ A comprehensive PDF will also link muscle function to movement and posture․

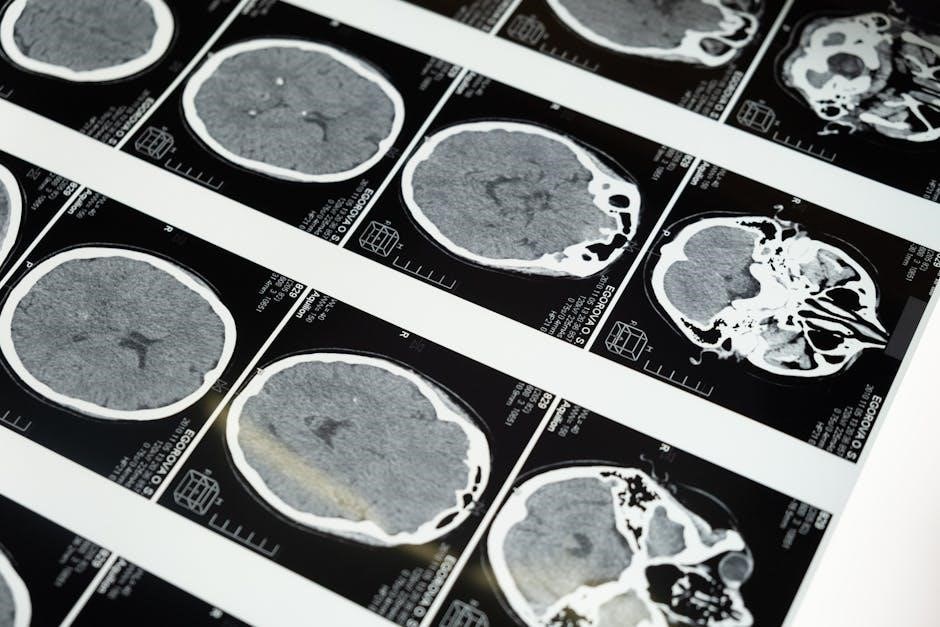

Nervous System

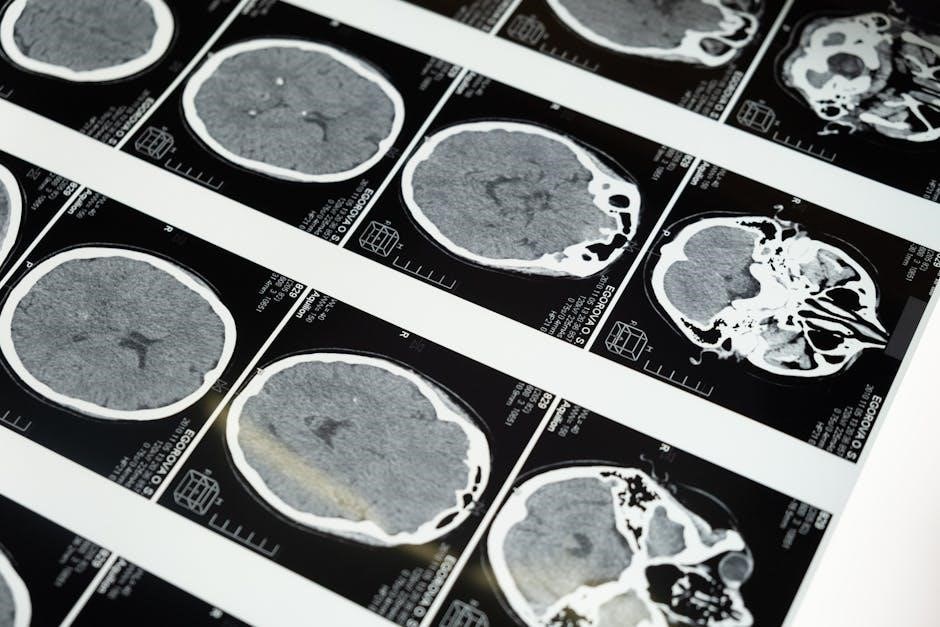

An effective anatomy and physiology 1 study guide PDF dedicates significant attention to the Nervous System, beginning with its fundamental divisions: central (brain and spinal cord) and peripheral․ It should detail the cellular components – neurons and glial cells – and their respective functions․

Key areas include neuronal structure, action potential generation, synaptic transmission, and neurotransmitters․ The guide must cover brain regions and their associated functions, alongside spinal cord anatomy and reflexes․

Understanding sensory and motor pathways, as well as the autonomic nervous system (sympathetic and parasympathetic), is crucial․

Diagrams illustrating brain anatomy, neuronal pathways, and reflex arcs are essential․ A strong PDF will connect nervous system function to overall body control and homeostasis․

Cardiovascular System

A robust anatomy and physiology 1 study guide PDF thoroughly examines the Cardiovascular System, starting with the heart’s anatomy – chambers, valves, and major vessels․ It details the flow of blood through the heart and the systemic and pulmonary circuits․

Essential components include understanding blood composition, blood pressure regulation, and the different types of blood vessels (arteries, veins, capillaries)․ The guide should explain cardiac muscle physiology and the cardiac cycle․

Coverage must extend to the lymphatic system’s role in fluid balance and immunity․

Illustrations depicting heart anatomy, blood flow patterns, and vessel structures are vital․ A comprehensive PDF connects cardiovascular function to oxygen delivery, waste removal, and overall body homeostasis․

Respiratory System

A detailed anatomy and physiology 1 study guide PDF provides a comprehensive overview of the Respiratory System, beginning with the upper and lower respiratory tracts’ anatomy․ It should cover the nasal cavity, pharynx, larynx, trachea, bronchi, and lungs․

Key areas include understanding the mechanics of breathing – inhalation and exhalation – and the role of the diaphragm and intercostal muscles․ Gas exchange, specifically oxygen and carbon dioxide transport, is crucial․

The guide must explain lung volumes and capacities, as well as factors affecting ventilation․

Visual aids like diagrams of the respiratory pathways and alveoli are essential․ A complete PDF connects respiratory function to cellular respiration and maintaining blood pH homeostasis․

Digestive System

Anatomy and physiology 1 study guide PDFs thoroughly explore the Digestive System, detailing its organs from mouth to anus․ This includes the esophagus, stomach, small intestine (duodenum, jejunum, ileum), large intestine, liver, pancreas, and gallbladder․

Essential topics cover mechanical and chemical digestion, enzyme functions (amylase, protease, lipase), and nutrient absorption processes․ Peristalsis and segmentation’s roles in moving food are vital․

The guide should explain the different layers of the gastrointestinal tract and their functions․

Visual aids illustrating digestive processes and organ structures are crucial․ A complete PDF connects digestion to nutrient utilization and waste elimination, emphasizing homeostasis․

Endocrine System

Anatomy and physiology 1 study guide PDFs dedicate significant attention to the Endocrine System, detailing hormone-producing glands like the pituitary, thyroid, adrenals, pancreas, and gonads․

Key areas include hormone classification (steroid, protein, amine), mechanisms of hormone action (receptor binding, signal transduction), and feedback loops regulating hormone secretion․

The guide should cover specific hormones – insulin, glucagon, cortisol, epinephrine, growth hormone, and sex hormones – and their physiological effects․

Understanding how the endocrine system maintains homeostasis through hormonal control is vital․ Visual aids illustrating gland locations and hormone pathways enhance comprehension․ A comprehensive PDF links endocrine function to other body systems․

Reproductive System

Anatomy and physiology 1 study guide PDFs thoroughly explore both male and female Reproductive Systems, detailing their anatomical structures and physiological functions․

For males, this includes the testes, epididymis, vas deferens, seminal vesicles, prostate gland, and penis, alongside spermatogenesis and testosterone’s role․

For females, the guide covers the ovaries, fallopian tubes, uterus, vagina, and mammary glands, detailing oogenesis, the menstrual cycle, and hormonal control of reproduction․

Key concepts include gametogenesis, fertilization, pregnancy, and the hormonal regulation of reproductive processes․ Visual aids illustrating reproductive organs and cycles are crucial․ A good PDF will connect reproductive physiology to endocrine function and development․

Using A&P 1 Study Guides Effectively

Anatomy and Physiology 1 study guide PDFs are most effective when integrated with active learning strategies․ Don’t just passively read; actively engage with the material․

Utilize the guide to create flashcards for key terms and structures, and practice labeling diagrams․ Regular self-testing reinforces memory and identifies knowledge gaps․

Combine lecture notes, textbook readings, and lab materials with the study guide for a holistic understanding․ Focus on understanding the relationships between anatomical structures and physiological processes, not just memorization․

Effective guides divide content into lecture and lab sections, facilitating targeted study․ Prioritize areas where you struggle, and seek clarification from instructors or peers․

Key Terms and Structures to Know

A comprehensive A&P 1 study guide PDF should prioritize essential terminology․ Master definitions for anatomical directional terms (superior, inferior, medial, lateral) and planes of the body (sagittal, transverse, frontal)․

Focus on understanding fundamental concepts like homeostasis, cells, tissues, organs, and systems․ Key structures include bones of the skeletal system, major muscles, brain regions, heart chambers, and digestive organs․

Familiarize yourself with prefixes, suffixes, and root words to decipher complex anatomical terms․ Study guides often list these terms, aiding in memorization and comprehension․

Prioritize understanding the function of each structure alongside its anatomy․ Knowing these terms and structures forms the foundation for advanced A&P concepts․

Lecture vs․ Lab Study Guides

Effective A&P 1 study necessitates distinct approaches for lecture and lab components, as highlighted in many PDF guides․ Lecture guides emphasize theoretical concepts – chemical levels, homeostasis, and system functions – requiring note-taking and conceptual understanding․

Lab guides, conversely, focus on anatomical structures․ These guides aid in identifying body parts, understanding their spatial relationships, and mastering dissection techniques․ Utilize diagrams, models, and practical exercises․

A combined study strategy is crucial․ Integrate lecture knowledge with lab observations to solidify comprehension․ Some study guides are specifically divided to support this dual learning process, maximizing exam preparedness․

Remember, lecture provides the ‘why’, while lab delivers the ‘where’ – both are vital for A&P 1 success․

Preparing for A&P 1 Exams

Successful exam preparation for A&P 1 relies on consistent effort and strategic study habits, often aided by comprehensive PDF study guides․ Prioritize active recall – testing yourself rather than passively rereading notes․ Utilize flashcards for key terms and structures, and practice labeling diagrams․

Focus on understanding the relationships between anatomy and physiology; don’t memorize in isolation․ Review lecture notes, lab manuals, and assigned readings regularly․ Practice with sample exam questions to familiarize yourself with the format․

Time management is key․ Allocate sufficient study time for each topic, and avoid cramming․ Seek help from instructors or study groups when needed․ A well-structured study guide can significantly enhance your performance․

Resources for A&P 1 Study (PDFs & More)

Numerous resources are available to supplement your A&P 1 learning, including readily accessible PDF study guides․ Websites like Simple Studies offer comprehensive, free guides covering various science topics, including anatomy and physiology․ Explore online platforms for practice questions and interactive quizzes․

Consider utilizing exam-specific resources, such as guides designed for the HESI A&P exam, providing targeted preparation․ Instructors often provide supplementary materials, including lecture slides and study outlines․ Don’t overlook textbooks and lab manuals as foundational resources․

Dr․ Ron Girmus’s A&P faculty resources can also be beneficial․ Remember to evaluate the credibility of online sources before relying on them․

HESI A&P Exam Preparation

Dedicated preparation is crucial for success on the HESI Anatomy & Physiology exam․ Utilize specialized study guides designed specifically for the HESI, focusing on key concepts and frequently tested material․ Practice with numerous sample questions to familiarize yourself with the exam format and question types․

Review all major body systems – skeletal, muscular, nervous, cardiovascular, respiratory, digestive, endocrine, and reproductive – ensuring a strong understanding of their structures and functions․ Focus on areas where you feel less confident, revisiting lecture notes and textbook chapters․

Resources are available online to aid in your preparation, offering targeted study materials and practice tests․